waste egnine oil fractional distillation process to produce base oil

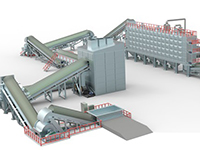

Feed / Waste engine oil

Capacity: from 1 ton per day to 300 ton per day.

Types of Waste engine oil / used motor oil

Output / Final products

3% - 5% Oil gas

10% - 12% Gasoline and diesel

75% - 80% Base oil (SN150, SN250)

5% - 10% Residue oil

Working condition:

High vacuum degree condition

200 - 300 degree Celsius

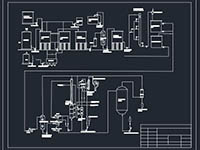

Process flow

How to produce high quality base oil?

RE:

The high temperature mass transfer purifier in the column is helpful to improve the distillation effect, to make the oil quality (color and odor) better.

The temperature on top of the distillation column is in the precise control. So that can separate light components (diesel and gasoline) completely. So that final base oil is of good viscosity and color.

The high vacuum distilling condition can protect the base oil ((C20-C40)) from being cracked (C10 - C22).

There are refluxing pipelines in the middle of column. Once the quality of base oil cannot reach process standard, the base oil will reflux into the distillation column for deep process.

The stainless steel packing in the distillation column will long the distillation route and remove suspended matter (impurities). So that can improve the distillation effect to the uttermost.

The whole process can be adjusted flexibly according to the characteristics of raw materials. To some raw materials, adding some flocculants during dehydration process is helpful to improve the oil quality. To some raw materials, adding some antioxidant after distillation is helpful to improve the color. The flexible choose will be helpful to save the cost.

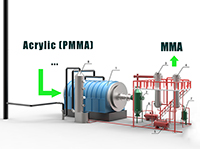

What is fractional distillation process?

How to guarantee the quality of fractional distillation column?

What is the differencesimple distillationandfractional distillation?

RE:

The simple distillation adopts simple distillation pipe, that is hard to complete separation of diesel, gasoline and base oil. Meanwhile, there is no tower internal parts and packing for filter. So that produces unqualified base oil.

The fractional distillation adopts precise fractional distillation column. The reacting condition would be controlled precisely, for completing the separation and filter very well.

The details of fractional distillation is as follows:

Structure of distillation column 1st section: fractional section 2nd section: rectifying section 3rd section: stripping section 4th section: Base | Specification of end products Side cut 1: light fraction: Gasoline diesel & gas Side cut 2: middle fraction: base oil Bottom residue: heavy fraction: asphalt |

Function of stripping section, rectifying section and reflux process:

The key operation of producing high quality oil, is the control of reflux ratio, mass transfer rate and temperature.

The stripping section and rectifying section is to filter the impurities and absorb the color, with high efficiency packing and proper tower internals. The filter effect is 150% as that of clay filtering process.

When raw oil comes into the stripping section, it will break the balance of gas and liquid. More light fractions will go out from heavy fraction.

When raw oil rise to the rectifying section, the oil will be purified by high efficiency packing and tower internals.

When light fraction meets the back-flow middle fractions, the back-flow middle fraction works as an absorbent, it would absorb the impurities and color from the light fraction. Meanwhile, the light fraction will break the balance of middle fraction, so that more purified light fraction will go out from middle fraction.

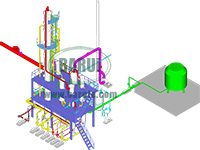

150 T/P base oil fractional distillation refinery

60TPD base oil fractional distillation refinery

Base oil storage zone